More Information

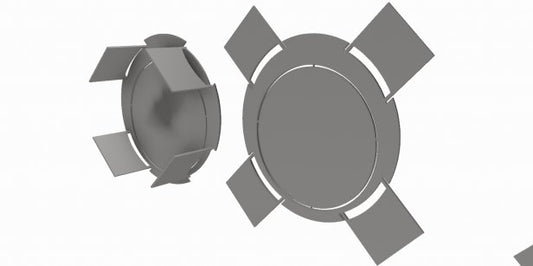

With a strong, durable ductile iron top section (option of steel for pedestrian use), this slot drain system combines steel side walls and Twinwall conduit to make it the perfect solution for all external drainage applications.

What are the benefits of using Swarm Aqua®?

-

Superior aesthetic finish

The narrow design of the slot drain means that less material is exposed than other linear drainage systems, making it less obtrusive. Also, with a choice of cast iron, steel or stainless steel tops, you can achieve a far superior finish. -

Simple to install

You don’t need to assemble Swarm Aqua® on site and because it has push-fit connections with a range of easy to use accessories, it is quicker and simpler to install than other drainage systems. -

Cost-effective

When installing over large drainage areas, Swarm Aqua® provides you with a more cost-effective drainage solution. The light-weight nature of the product can also save you on transport and installation costs. -

Ideal in heavy load traffic areas

The strong, durable design of Swarm Aqua® means that when installed with a full concrete surround, it can be used in areas of heavy loading traffic up to F900. -

Ideal in high traffic pedestrian areas

With only two 10mm openings visible at the surface level of Swarm Aqua®, this system is safe to use in areas of high pedestrian traffic. -

Long design life

The twinwall channel is manufactured from 100% recyclable material and is resistant to a range of chemicals, with a predicted design life of over 60 years.

- Choice of strong, durable ductile iron, steel or stainless steel tops

- Only two 10 mm heel guards openings visible once installed

- Steel walls to provide excellent rigidity when installing

- Spacers used to prevent pinching and act as locators to ensure a positive connection when installing

- Push-fit connections to ensure a quick and simple installation

- Steel throat section to withstand higher vertical loads and shear forces

- Smooth bore, giving excellent hydraulic properties

- Channel manufactured to SN6, with a predicted design life over 60 years

- HDPE section made from 100% recycled material

- From loading A15 to F900.

Product added to cart ✓