Twinwall Drainage System: A Step-by-Step Guide for Installation

Twinwall drainage systems are essential for managing surface water effectively in residential, agricultural, and commercial settings. Known for their durability, twinwall pipes are designed to handle high-pressure loads while maintaining efficient water flow. Whether you're tackling field drainage or a large-scale infrastructure project, this guide will help you install a twinwall drainage system with ease.

For high-quality twinwall products, check out Cotterill Civils’ twinwall drainage pipe collection.

What Are Twinwall Drainage Pipes?

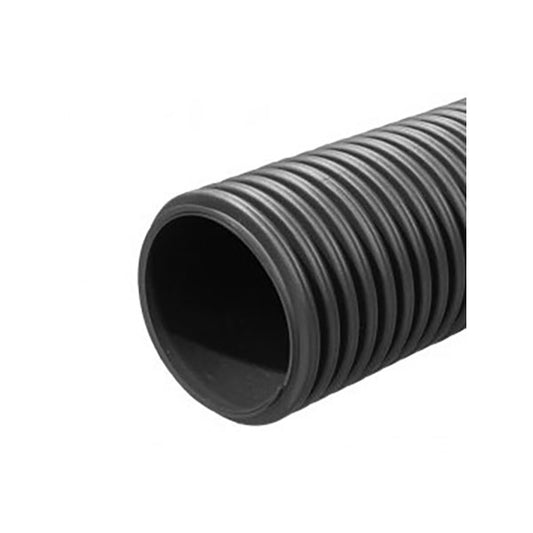

Twinwall pipes are made from high-density polyethylene (HDPE) and feature:

- A corrugated outer wall: Provides extra strength and resistance to external pressure.

- A smooth inner wall: Ensures optimal water flow with minimal resistance.

They’re suitable for applications like:

- Field drainage: Preventing waterlogging in agricultural settings.

- Road and highway projects: Managing surface runoff and preventing water damage.

- Residential and commercial developments: Addressing drainage issues effectively.

Tools and Materials You’ll Need

To ensure a smooth installation process, gather the following:

- Twinwall pipes (available in various diameters and lengths).

- Pipe connectors, couplers, and end caps.

- Geotextile membrane for filtration.

- Gravel or pea shingle for bedding and backfill.

- Excavator or trenching tools.

- Measuring tape and spirit level.

Discover top-quality twinwall drainage accessories to complete your setup.

Step 1: Planning Your Twinwall Drainage System

-

Assess Your Site:

Determine areas prone to waterlogging or poor drainage. Identify natural slopes and plan where to lay the pipes. -

Calculate Pipe Size and Length:

Use the diameter and length based on the anticipated water volume and distance. Our team can assist in choosing the correct size. -

Design the Layout:

Plan trench routes, ensuring they follow a consistent gradient of approximately 1:100 for effective water flow.

Step 2: Excavating the Trenches

Prepare the site by:

- Digging trenches wide enough to accommodate the pipes and backfill.

- Ensuring a consistent gradient to direct water flow.

- Removing large rocks or debris from the trench base to prevent damage.

Step 3: Preparing the Base

A stable base is essential for system durability:

- Add a 50-100mm layer of compacted gravel or pea shingle to the trench.

- Use a spirit level to confirm the base maintains the required slope.

Step 4: Laying the Twinwall Pipes

Install the pipes as follows:

- Place the twinwall pipes in the prepared trench, ensuring they align with the planned layout.

- Connect pipe sections using pipe connectors and couplers to create a secure and leak-free system.

- Wrap geotextile membrane around the joints to prevent soil ingress.

For heavy-duty projects, consider Cherry Twinwall Pipes for added durability.

Step 5: Backfilling the Trenches

Protect your system with proper backfilling:

- Cover the pipes with an initial layer of gravel or pea shingle for stability and drainage.

- Backfill the rest of the trench with excavated soil, compacting lightly to avoid shifting.

- Ensure inlets and outlets remain accessible for future maintenance.

Step 6: Testing the System

Before finalising your project:

- Flush water through the system to check for proper flow and detect blockages.

- Adjust the slope or remove obstructions as needed to ensure optimal functionality.

Maintenance Tips for Twinwall Drainage Systems

- Inspect pipe inlets and outlets regularly to prevent debris build-up.

- Flush the system periodically to remove sediment.

- Replace damaged components promptly to maintain performance.

FAQs About Twinwall Drainage Systems

What is twinwall drainage used for?

Twinwall drainage is ideal for managing surface water in fields, construction sites, and residential areas.

How deep should twinwall pipes be installed?

Pipes should be buried at least 500mm below the surface to protect them from damage.

What sizes are twinwall pipes available in?

Twinwall pipes come in a variety of diameters, such as 110mm, 150mm, and 300mm, depending on your project requirements.

Why Choose Cotterill Civils for Twinwall Drainage?

At Cotterill Civils, we offer a comprehensive range of twinwall drainage pipes and accessories to meet the demands of any project. Our product selection includes trusted brands like Cherry and our own Cotterill Civils, known for their durability and performance. With expert advice and high-quality products, we ensure your drainage system is efficient and long-lasting. For more information visit our website or contact our expert team today on 0121 351 3230