Vortex Flow Control Valves and Orifice Flow Control Chambers are used to manage Sustainable Drainage Systems (SuDS) and protect sewer infrastructure as part of a designed attenuation system. Both are highly effective; if you’re deciding which to use, here’s a quick guide to how they work and how they differ.

What are the systems used for?

Both systems sit alongside an attenuation solution to control the discharge of stormwater and help prevent flooding. With increasing areas of hard-surfaced, urbanised land in the UK, SuDS are a growing priority for developers and local authorities, and are being strongly encouraged by UK policy.

What is a Vortex Flow Control system?

A Vortex Flow Control is a self-activating device based on vortex hydrodynamics. It uses hydraulic effects—without moving parts or external power—to regulate outflow.

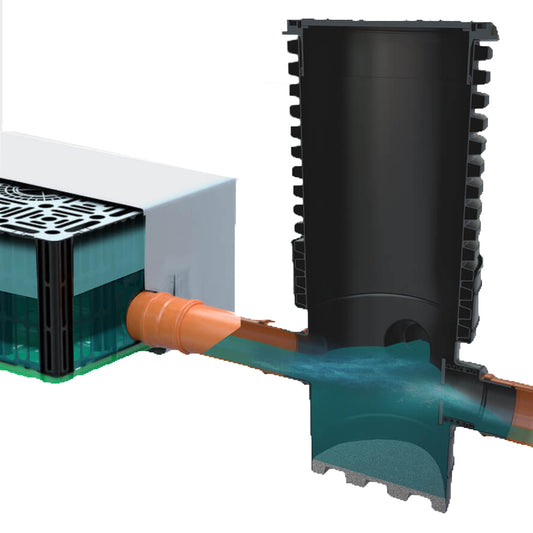

As the upstream water level rises, a controlled vortex is induced. The swirling motion dissipates energy, creating a pressure drop across the device and restricting discharge at the outlet to a pre-engineered rate.

What is an Orifice Flow Control system?

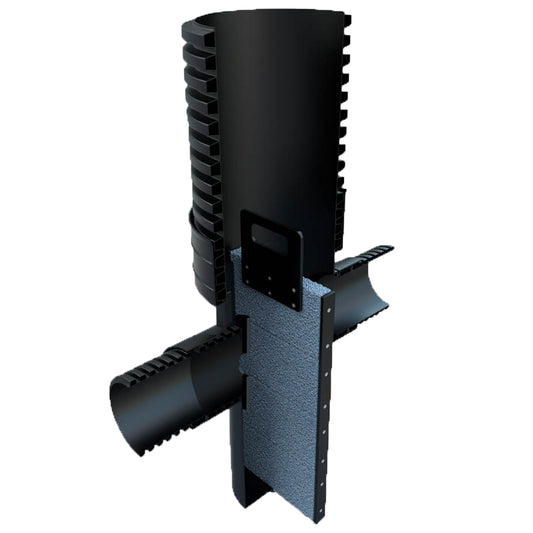

Orifice Flow Control systems are pre-fabricated twin-wall chambers incorporating an orifice plate. The plate provides a fixed hydraulic restriction to regulate flow and reduce downstream pressure.

Properly sized orifices offer precise discharge control and can be a simple, economical choice—especially where system demands and debris loads are modest.

What’s the difference between the two?

Both options can meet design discharge requirements—selection depends on site conditions, storage volume, debris load, maintenance strategy, and budget. Broadly, Vortex controls often suit larger schemes with higher debris risk, while Orifice controls can be ideal for smaller or simpler sites. Here are some of the key differences:

- Blockage risk: The outlet on a Vortex Flow Control can be up to six times larger than a traditional orifice plate for the same design flow, significantly reducing blockage risk and maintenance.

- Downstream protection: Vortex units dissipate more energy than Orifice Flow Controls, reducing scouring and potential damage to wetlands, ponds, basins, watercourses, or sewer infrastructure.

- Maintenance & Power: Vortex devices are self-activating with no moving parts or power supply—minimising maintenance needs.

- Installation speed: An Orifice Flow Control chamber is delivered as a one-piece unit, ready to install—reducing time on site and overall installation costs.

- Footprint & Cost: Orifice chambers can reduce land take at the final outfall and offer savings compared to larger bespoke flow control chambers.

- Handling: Orifice chambers are strong yet lighter in weight than Vortex units, helping to reduce manual handling risks.

How can we help?

We supply a full range of Vortex Flow Control and Orifice Flow Control systems and can advise on sizing, siting, and specification to suit your SuDS design and budget. Call our specialists today on 0121 351 3230.

Alternatively, fill out our enquiry form: